WULFCRAFT BREWING

CONTRACT BREWING & PRODUCTION SUPPORT

Not a brewery… A brewer!

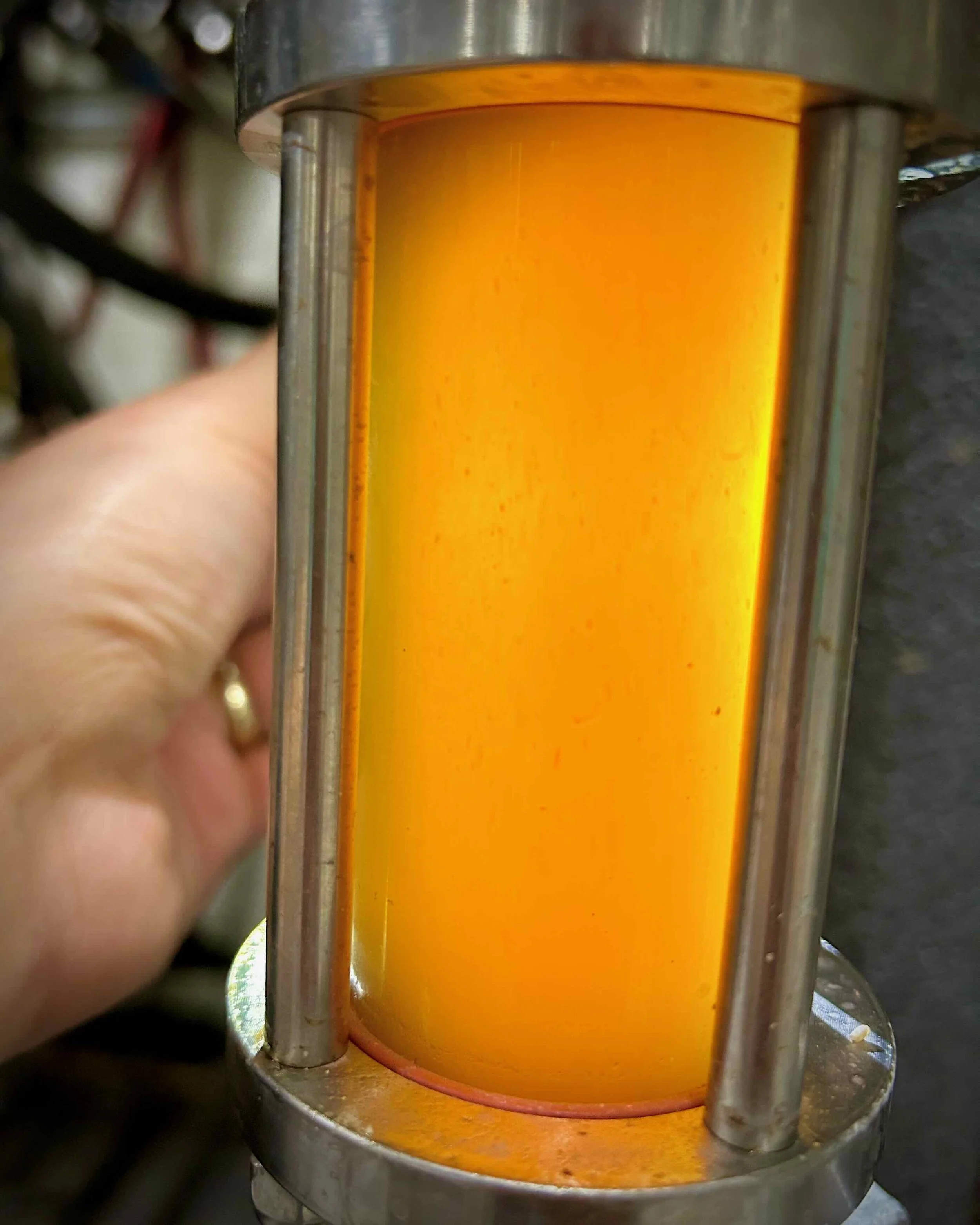

WulfCraft Brewing partners with existing breweries to provide skilled, contract-based production support—from brewhouse to packaging line.

services

on-site brewing support

From wort production to cellar work, I fill in where your team needs help most. Whether you’re short-staffed or up against a tight production deadline, I offer hands-on brewing support tailored to your SOPs and schedule.

Canning line operations

Keep your packaging line moving without the headaches. With years of canning experience, I can lead or support your canning runs—reducing downtime, maintaining quality control, and getting your product out the door on time.

Cellar management

Need help juggling tank transfers, yeast harvests, or CIP cycles? I’ll step in with a clean and methodical approach, so your beer stays on schedule and your tanks stay in rotation.

Recipe development

Looking to experiment? I can help you test new concepts, scale recipes, or design seasonal offerings with your system and market in mind.

production consultation

Let’s dial in your system. I can help troubleshoot inefficiencies, identify quality gaps, and streamline production workflows—from brewhouse to bright-tank.

Maintenance & Training

Whether you’re onboarding new production staff or reworking your SOPs, I offer one-on-one training and consulting to help build confident, efficient teams that take pride in the craft.

My name is Kevin Wulf. I’m a contract brewer and production specialist with over a decade of hands-on experience in the craft beer industry. I’ve worked my way up from assistant brewer to head of production, managing everything from pilot systems to 30-barrel brewhouses, and leading canning lines, cellar teams, and full-scale recipe development.

Before launching Wulfcraft Brewing, I ran production for Riverwalk Brewing Co., led the brewing team at Gentile Brewing, and collaborated with over a dozen breweries from all over the North Shore and Greater Boston area to bring their contract recipes to life. I’ve built cask programs, scaled 5 - gallon recipes to 15/30/60 bbl batches, and kept operations running clean, lean, and efficient — always with an eye on quality and craft.

These days, I work directly with breweries who need skilled, short-term brewing support: filling gaps, scaling and developing new recipes, and keeping the tanks turning. When I’m not in the brewhouse, you’ll probably find me deep in a woodworking project or baking a fresh loaf of bread.

Get to know your brewer

Our partners

Don’t Take My Word For It

“Having Kevin on board has been a huge help to me and the brewery. He’s reliable, communicates clearly, and takes pride in his work, whether it’s brewing, cellaring, maintenance projects, or developing new recipes. His consistency and professionalism have allowed me to focus more on other parts of the business, knowing the production side is in good hands.”

— Paul Gentile (Owner, Brewer at Gentile Brewing Company)

“Kevin’s assistance on the production floor provides the most valuable resource for a business owner: peace of mind. We can be certain that Kevin will always be looking out for the best interests of our organization.”

— Steve Sanderson (Owner of Riverwalk Brewing Company)

Drop me a line

Brewing backups, production bottlenecks, or canning chaos?

Let’s get that sorted!

Use the form to get in touch. No job too big, no brew too small.

Based in Massachusetts. Available for on-site projects throughout the Greater Boston Area and North Shore.

Remote consultation available for all other inquiries.